HULL INNOVATIVE SYSTEM

INTRODUCTION

Hull Innovative System by Ranieri International

- it is rigid in rough waters, especially when the hull overtakes the wave,

- it worsens the comfort,

- it does not allow you to keep a precise sea route, especially with speed;

- it is weak from a structural point of view;

- it creates splashes

These drawbacks have prompted the designers, over the course of many decades, to seek a compromise between a flat bottom and a wedge-shaped hull (called “V-shaped hull“), which improves seakeeping and softens vertical impacts on the waves; it also provides less lift because the pressure on the bottom is not perfectly vertical but perpendicular to the surface instead.

This explains the development and rapid diffusion of the “V” hull: the more pronounced it is, the more sea-worthy it becomes. This particular hull, in fact, softens the impact on the waves, but at the same time creates more resistance, therefore lower performances in calm waters: the higher is the speed to push an ideal hull, the greater is the resistance and friction to it.

In an attempt of identifying the best possible hull geometry – with lower friction of the hull on the water and same performances – Ranieri International has created and developed over the years the HIS, which stands for Hull Innovative System.

The H.I.S. was developed in aeronautics since the ’20s when seaplanes started to become popular worldwide: the goal was to increase the speed during take-off while maintaining stability during landing. These studies led to the identification of some very effective solutions such as precisely, the redan (or step).

The solution is actually very complex in its design and construction; it consists of ventilating the hull, which is able now to forcibly channel air between the hull and the water. That creates a real cushion of air and water which reduces the friction of the hull while maintaining its lift. This mechanism is more effective at higher speed and it is created by a particular hull design with “steps” (or redan).

This discontinuity in the hull causes the flow of water to be interrupted at the point where the step is located, only to impact the hull again further back.

The air gap created – between the “detachment” point and the “rejoining” point – is filled by water splashes and by air, that is sucked from the hull side edges. This mechanism allows a “lubrication” of the bottom by “sucking” the air outside, it facilitates the planing, it decreases the resistance to friction, it improves stability and it eliminates the rhythmic oscillation of the boat.

With the H.I.S., the area of the hull in contact with the water is divided into two smaller areas: that helps to reduce the resistance, it improves the performance and the stability as well as the running, all to the advantage of higher speed and lower consumption. The fragmentation of the hull determined by the H.I.S. allows to have variations on the deadrise and different stringers between the steps; this means that each area of the hull works as if it were a hull in its own, right with its own characteristics of lift and resistance.

Ranieri International has tested and proved over many years, the effectiveness of the redan and, thanks to the knowledge acquired and researches on the effects of fluid dynamics, has decided to adopt its application on all its models.

Hull Innovative System Generation II - by Ranieri International

The evolution of the boating industry over the last several years has seen an increasing demand for larger and more performing boats and ribs; the shipyard has created, therefore, new models and has tuned up new technologies and construction processes, more suitable for the new market and the release of more powerful engines.

Thanks to the boost from the market, boats have reached very high speeds these days and consequently very high fluid dynamic characteristics.

By taking all these results into consideration, along with five decades of experience, Ranieri International has designed a second-generation HIS, featuring an important increase in the volume of air inlets under the hull, to ensure a more effective function of the “steps”.

The development of a new generation H.I.S. was possible thanks to the many resources and energies (in terms of both financial and time), and many different designs and tests.

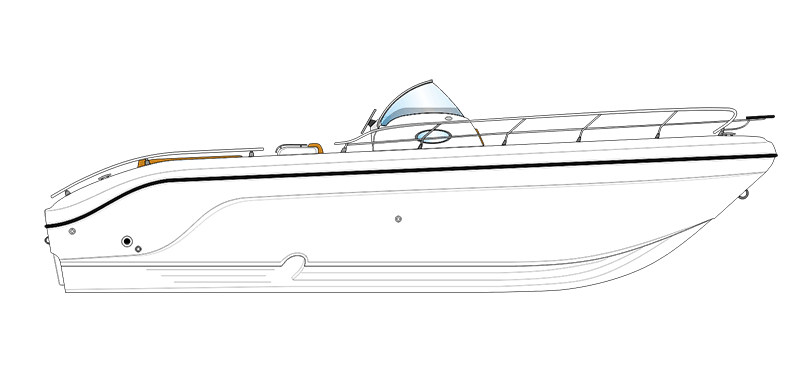

This new generation of hulls features new geometries, a different shape, different chines, and new air intakes (redan). It is also well visible from the profile with the characteristic “double-step” shape called the Twin Air Step System. The typical “funnel” design forces the entry of the air generated by the speed in the longitudinal tunnels; that air is channeled and distributed on the bottom afterward. The new shape of the redan, the location, and the increased number of it (two steps), significantly improved the performance and comfort of the new generation of hulls.

Ranieri International couldn’t be more thrilled about the results, so much so that has decided to introduce this new technology to the whole range of boats and ribs, even if the smallest models present higher production costs due to the increased number of reinforcements needed in the area of the step.

Thanks to the H.I.S. and its evolution, Ranieri International has managed to combine performance and comfort in rough waters with low fuel consumption.

Technology and the development of the redans have helped the yard to achieve incredible results and Ranieri International confirms, once again, to be one of the few shipyards in the industry to invest in R&D also for small-medium size boats.